Welcome To Our Official Website, And We Will Provide You With Excellent Service.

🧶 Must-Know 9 Common Knitting Structures for Sweater Enthusiasts

If you’re passionate about sweaters or work with a knitting factory in China, understanding the fundamentals of knitting structures is essential. Each stitch type creates a distinct texture, elasticity, and visual effect — all of which determine the final feel and performance of your knitwear.

As a custom sweater manufacturer with years of experience, Dongguan Chuangdian Garment Factory is here to walk you through the 9 most common knitting structures used in modern knitwear design and production.

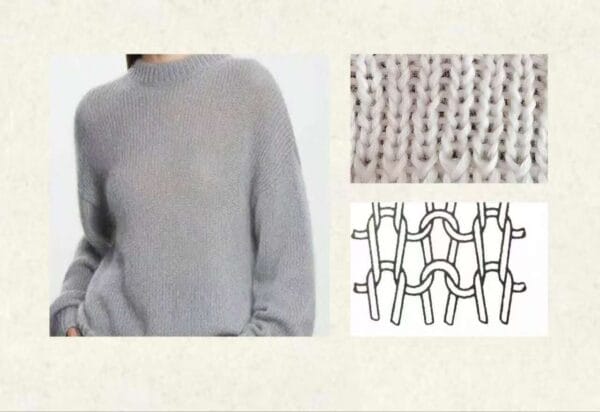

1️⃣ Plain Weave

Also known as the flat stitch structure, the plain weave is the simplest and most classic single-sided knitting structure. On flat knitting machines, this produces single jersey fabrics — smooth on the front and slightly textured on the back.

🧥 Applications: lightweight sweaters, T-shirts, underwear, and pajamas.

Features: smooth surface, good drape, and high flexibility.

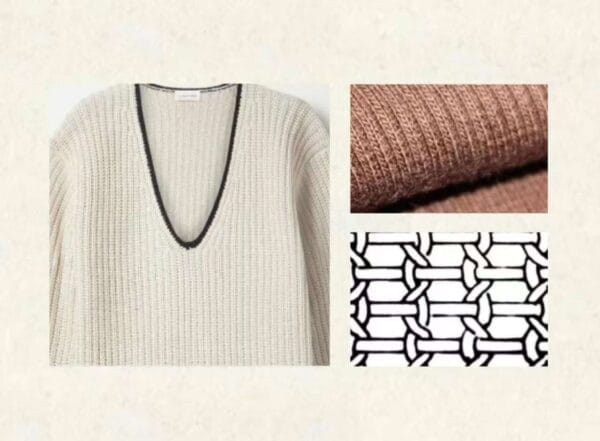

2️⃣ Rib Weave

Rib weave is the fundamental structure of double-sided weft knitting, created by alternating front and back wales in a regular order. Known for its excellent elasticity, it’s commonly used in garments that require stretch recovery.

🧥 Applications: sweater hems, cuffs, collars, and body-fitting knitwear.

Features: excellent elasticity, shape retention, and comfort.

3️⃣ Purl Weave

Purl weave alternates front and back loops on successive courses, giving both sides a texture similar to the back of plain weave. The fabric is soft, thick, and stretchable.

🧥 Applications: baby knitwear, children’s clothing, and warm undergarments.

Features: reversible texture, excellent warmth, and elasticity.

4️⃣ Interlock Weave

The interlock weave is a compound structure formed by two rib weaves interlocked together. This double-sided weft knitting structure, also known as cotton interlock, creates a dense and stable fabric.

🧥 Applications: underwear, sportswear, casualwear, and kids’ sets.

Features: smooth surface, good opacity, and strong dimensional stability.

5️⃣ Tuck Stitch

In tuck stitch, certain needles hold their loops for one or more courses before knitting again. This creates a textured surface with a soft, elastic hand feel and a rich visual pattern.

🧥 Applications: shawls, scarves, textured panels in sweaters.

Features: 3D texture, breathability, and decorative versatility.

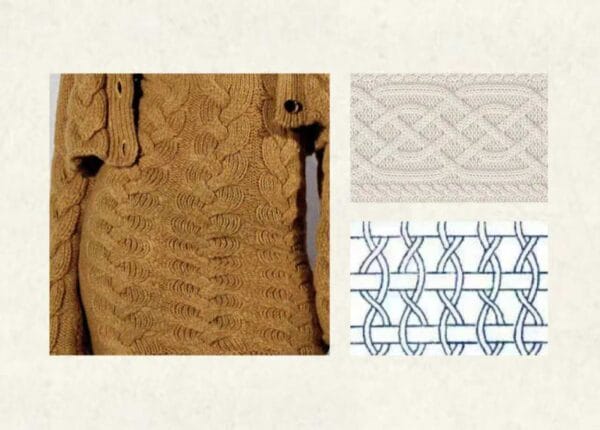

6️⃣ Jacquard Weave

Jacquard weave is created by selectively knitting yarns on specific needles according to a design pattern. It can be single-sided or double-sided and is widely used in patterned sweaters and decorative knitwear.

🧥 Applications: jacquard pullovers, outerwear, and fashion accessories.

Features: diverse pattern expression, color versatility, and high-end appearance.

7️⃣ Sandwich Quilting

Sandwich quilting is a unique technique knitted on double-sided machines, combining single- and double-knit layers. Non-knitted weft yarns are inserted between the layers, creating a quilted, padded effect.

🧥 Applications: winter sweaters, quilted tops, thermal wear.

Features: thick texture, soft warmth, and structured appearance.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

8️⃣ Terry Weave

Terry weave combines plain loops with elongated sinker loops to create terry or looped textures. After shearing and finishing, it becomes velour, known for its luxurious softness.

🧥 Applications: towels, pajamas, babywear, bathrobes.

Features: excellent absorbency, warmth, and plush comfort.

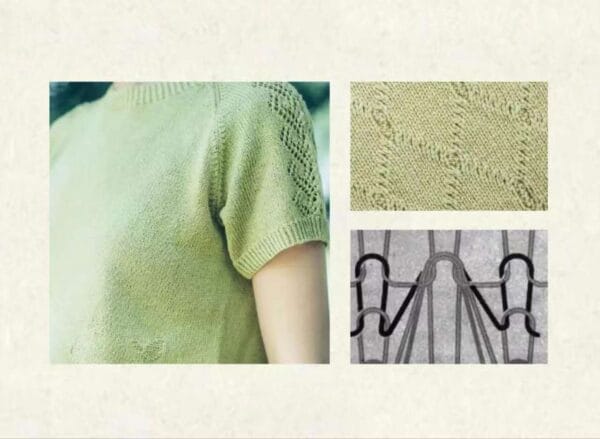

9️⃣ Mesh or Openwork Stitch

Also known as loop transfer knitting, leno weave forms openwork or mesh-like structures by transferring stitches according to the pattern design. It can create lace-like holes, cables, and Aran-style textures.

🧥 Applications: lace sweaters, mesh cardigans, breathable summer knits.

Features: transparency, decorative depth, and pattern flexibility.

🧵 Final Thoughts

From plain jersey to Aran-style leno stitches, these knitting structures are the foundation of sweater design and innovation. Understanding them helps you communicate better with your OEM knitwear factory and ensures your products achieve the desired style and performance.

At Dongguan Chuangdian Garment Factory, we combine craftsmanship with advanced computerized flat knitting machines (3GG–14GG) to create both classic and customized knitwear for global brands.

📩 Looking for a reliable knitting factory in China?

Let’s turn your creative designs into beautifully made sweaters.