Welcome To Our Official Website, And We Will Provide You With Excellent Service.

What Is a 3D Knit Sweater? A Game-Changing Seamless Technology

In today’s fast-evolving fashion world, innovation drives everything — from design concepts to manufacturing methods. One remarkable breakthrough that’s redefining knitwear is the 3D knit sweater. This technology is transforming how garments are produced, making them more comfortable, sustainable, and precise than ever before.

Understanding 3D Knit Sweaters

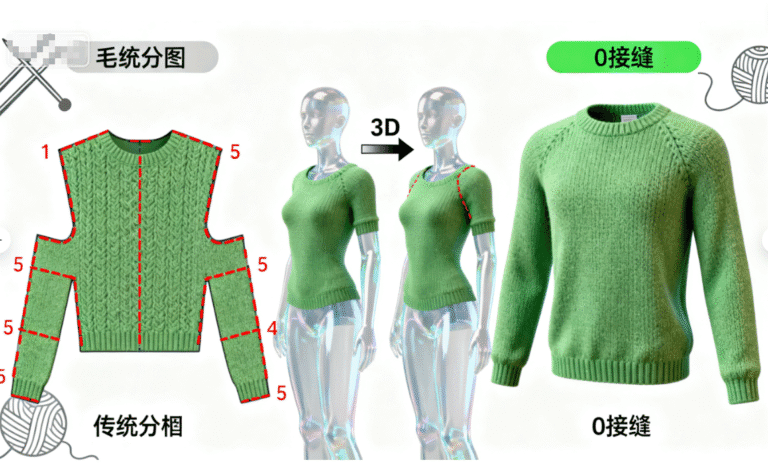

A 3D knit sweater is made using advanced computerized knitting technology that creates an entire garment in one seamless piece. Unlike traditional methods — where flat panels of fabric are cut and stitched together — 3D knitting eliminates the need for seams.

This technique allows each sweater to be produced as a fully formed, three-dimensional item, perfectly shaped to the body’s contours. The result is a piece of knitwear that feels softer, fits better, and looks smoother — no uncomfortable seams or bulky stitching.

How 3D Knitwear Is Made

The creation process relies on computerized flat knitting machines such as SHIMA SEIKI’s WHOLEGARMENT® technology. Designers first create a digital pattern that defines every stitch, texture, and detail. The machine then interprets this data, knitting the garment directly in three dimensions.

Because the sweater is produced in one continuous operation, it requires little to no post-production sewing. This not only saves time but also minimizes material waste — a key step toward sustainable garment manufacturing.

Benefits of 3D Knit Sweaters

1. Seamless Comfort

Without seams, the garment has a smooth and comfortable finish. There are no hard edges or inner stitching to irritate the skin — ideal for everyday wear or performance apparel.

2. Precision Fit

3D knitting allows designers to adjust every dimension digitally, ensuring an exact fit tailored to the wearer’s body. This technology bridges the gap between customization and mass production.

3. Enhanced Durability

Seams are often the weakest part of a traditional sweater. By removing them, 3D knitwear becomes stronger and less prone to tearing or fraying, extending the life of the garment.

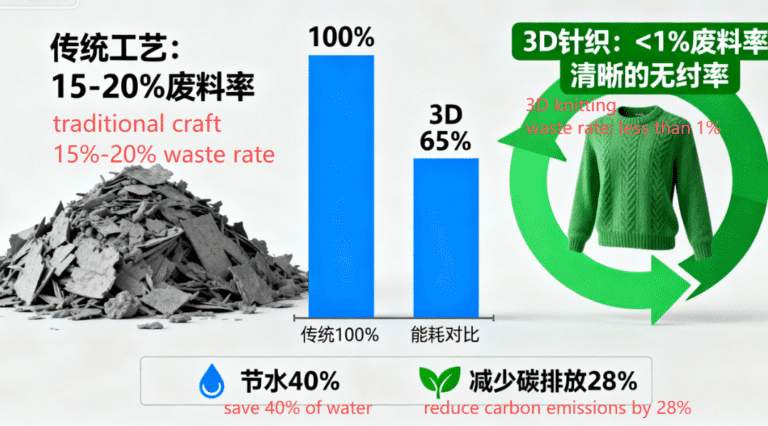

4. Eco-Friendly Manufacturing

Compared with cut-and-sew production, 3D knitting dramatically reduces fabric waste. The process also consumes less energy and shortens production time, aligning perfectly with the fashion industry’s move toward sustainability.

5. Design Flexibility

From complex textures to integrated patterns and multi-yarn effects, 3D knitting allows limitless creativity. Designers can experiment with new structures and shapes without sacrificing function or comfort.

Why 3D Knitwear Matters

The rise of 3D knitwear reflects a major shift toward sustainable, intelligent fashion production. Brands are increasingly adopting this method to reduce environmental impact while delivering garments that meet modern consumers’ expectations for comfort, performance, and personalization.

For fashion designers, retailers, and manufacturers, 3D knitting opens up new possibilities — not just in how sweaters are made, but in how the fashion industry envisions the future of clothing.

Final Thoughts

3D knit sweaters represent the next chapter in knitwear innovation — seamless, sustainable, and incredibly precise. Choosing the right manufacturer with expertise in 3D knitting technology ensures your products meet the highest standards in both quality and sustainability.

As consumers continue to value comfort and eco-consciousness, investing in 3D knitwear isn’t just following a trend — it’s embracing the future of fashion.

-35-2-768x432.png)

-21-768x432.png)