Welcome To Our Official Website, And We Will Provide You With Excellent Service.

The Craftsmanship Behind Quality Garments, From Fabric to Finish

Garment Technology

Garment craftsmanship serves as a bridge transforming designers’ creativity into tangible clothing, and it is a comprehensive discipline integrating technology and art. The birth of a high-quality garment requires meticulous design, precise cutting, exquisite sewing, careful ironing and other multiple processes. Below, we will fully analyze the complete technological process of modern garment production and reveal the craftsmanship behind a piece of clothing.

I. Design and R&D: The Starting Point of Creativity

Design and Development Process:

Inspiration Collection: Capture fashion trends, study consumer preferences and analyze competitor characteristics to determine the design direction.

Sketching: Transform inspiration into visual design schemes, defining styles, silhouettes and details.

Pattern Making: Convert 2D designs into 3D garment structure patterns through manual work or CAD systems.

Sample Garment Production: Cut fabrics and sew samples according to patterns, then conduct fitting and adjustments.

Core Value:

Excellent design not only pursues aesthetics but also balances wearing comfort and functionality, serving as the primary guarantee of garment quality.

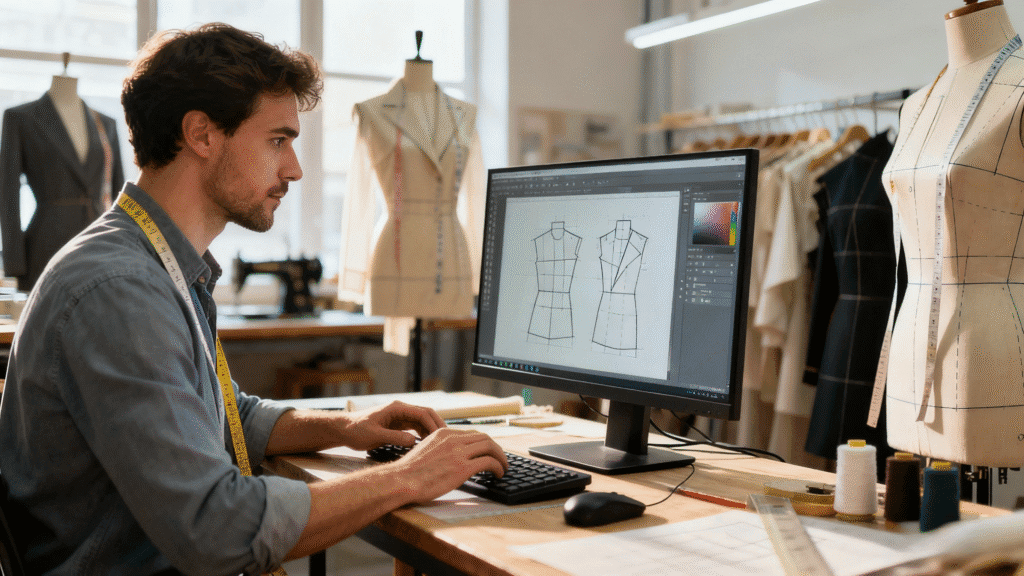

Figure 1: A fashion designer sketching in the studioimage

II. Fabrics and Accessories: The Soul of Garments

Key Factors for Fabric Selection:

FactorsExplanationMaterial PropertiesCotton (breathable), linen (cool), silk (luxurious), wool (warm), chemical fibers (durable), etc.Texture and Hand FeelSoftness, smoothness, drape, etc., directly affecting the wearing experience.Color FastnessThe ability to resist fading, related to the service life of garments.Application ScenariosCasual wear, formal wear, sportswear, special functions (waterproof, flame-retardant), etc.

Fabric and Accessory Inspection

Process:

Quantity counting and appearance inspection (color difference, defects)

Intrinsic quality testing (shrinkage rate, color fastness, strength)

Preshrinking treatment (for deformable fabrics)

Classified storage, moisture-proof and insect-proof

Figure 2: Various fabrics neatly arranged in a fabric warehouse

image

III. Cutting Technology: The Art of Precision

Cutting Process Flow:

Marker Making: Scientifically arrange patterns on fabrics to maximize fabric utilization (up to over 90%), while considering fabric directionality and pattern symmetry.

Fabric Fixing: Use clips or tape to fix fabrics during multi-layer cutting to prevent displacement.

Cutting Operations:

Manual Cutting: Suitable for custom-made single pieces, using professional scissors with high precision.

Mechanical Cutting: Electric scissors or cutting beds, high efficiency, suitable for mass production.

Laser Cutting: Extremely high precision, suitable for complex patterns and special fabrics.

Cutting Piece Finishing: Numbering, classification and marking for convenient subsequent sewing.

Technical Points:

Cutting precision directly affects the dimensional accuracy of finished garments, with errors controlled within ±0.2cm. Special techniques are required for special parts (collars, cuffs, etc.).

Figure 3: A professional tailor cutting fabrics with electric scissors

image

IV. Sewing Technology: The Skeleton and Blood Vessels of Garments

Sewing is the core of garment craftsmanship, endowing flat cutting pieces with three-dimensional life.

Basic Sewing Techniques:

Plain Sewing: The most basic stitch, used for connecting garment pieces.

Overlocking (Serger Sewing): Prevent fabric edges from fraying and enhance durability.

Topstitching: Decorative stitches to improve visual effect.

Special Sewing: Professional techniques for special parts such as pockets, collars and cuffs.

Characteristics of Modern Sewing:

Industrial production adopts “unit synchronization” operation, increasing efficiency by more than 30%.

Computer-controlled sewing machines achieve precise stitches and complex patterns.

Automated guided vehicle (AGV) systems intelligently transport cutting pieces between processes.

Sewing Sequence Principle:

“Inside out first, small parts before large parts, difficult parts before easy parts”. For example, handle darts and pockets first, then sew side seams and shoulder seams.

Figure 4: Workers operating sewing machines to sew garments in a clothing factory workshop

image

V. Ironing and Shaping: The Final Shaping of Garments

Three Major Functions of Ironing:

Smoothing: Eliminate wrinkles during sewing and make the garment surface smooth.

Shaping: Mold the three-dimensional silhouette of garments (such as suit lapels, shirt collars).

Enhancing Texture: Improve fabric luster and hand feel.

Detailed Explanation of Ironing Techniques:

TechniquesOperation MethodsApplication ScenariosPressing and PushingPush the iron forward, used for protruding parts such as chest and backSuits, coats and other garments requiring three-dimensional effectsShrinking IroningShrink the fabric edge toward the center, suitable for convex parts of the human bodyShoulders, armholes and other parts requiring fitnessPressing and HoldingPress the iron heavily and stay briefly to enhance shaping effectShirt collars, cuffs, trouser creases and other parts requiring long-lasting crispnessSteam IroningTreat fabrics with high-temperature steam to restore elasticityVarious fabrics, especially natural fibers

Key Parameter Control:

Temperature (adjusted according to fabrics, such as 80-100℃ for silk, 120-150℃ for chemical fibers), humidity and pressure directly affect the ironing effect.

Figure 5: Professional ironing equipment shaping garments

VI. Finishing and Quality Control: Guardians of Quality

Finishing Processes:

Buttonholing and Button Sewing: Ensure buttons are firm and buttonholes are neat.

Thread Trimming: Clean all excess threads to improve the refined appearance.

Label Sewing: Washing instructions, size, brand logo, etc.

Strict Quality Inspection System:

First Piece Inspection: Confirm process standards before mass production.

In-Process Inspection: Random sampling during production to detect problems in a timely manner.

Full Finished Product Inspection: Inspect appearance, size, workmanship and functions one by one.

Physical and Chemical Testing: Professional testing for color fastness, washing dimensional stability, etc.

Inspection Standards:

Dimensional tolerance controlled within ±0.5cm.

Stitch density: 12-14 stitches per 3cm for visible stitches, 10-12 stitches per 3cm for invisible stitches.

Defects: No more than 2 defects per square meter, which do not affect use and appearance.

Figure 6: Quality inspectors conducting detailed inspections on finished garments

image

VII. Future Trends of Garment Craftsmanship

1. Intelligent Production:

AI-assisted design and pattern making, shortening the development cycle by more than 50%.

Fully automatic cutting beds and sewing machines, realizing “unmanned” production.

Virtual fitting technology, reducing sample garment production costs.

2. Sustainable Craftsmanship:

Zero-waste marker making systems, increasing fabric utilization to over 95%.

Environmentally friendly dyes and auxiliaries, reducing chemical pollution.

Detachable design, facilitating maintenance and recycling.

3. Personalized Customization:

Small-batch, multi-variety flexible production to meet personalized needs.

Customization services expanded from high-end fashion to daily wear for the general public.

Garment craftsmanship is undergoing a historic leap from traditional manual work to intelligent manufacturing, but its core value remains unchanged: through exquisite craftsmanship, endow fabrics with life and create comfortable and beautiful wearing experiences for people.

Conclusion

A perfect garment is the crystallization of designers’ inspiration and craftsmen’s skills, and the integration of technology and tradition. From fabric selection to final finished products, each process embodies the wisdom and sweat of countless people. Understanding garment craftsmanship not only helps us better appreciate the beauty of clothing but also allows us to pay more attention to quality details when purchasing and make more valuable consumption choices.

-35-2-768x432.png)

-21-768x432.png)