Welcome To Our Official Website, And We Will Provide You With Excellent Service.

The Language of Quality: Why Your “Tech Pack” is Your Best Insurance Policy

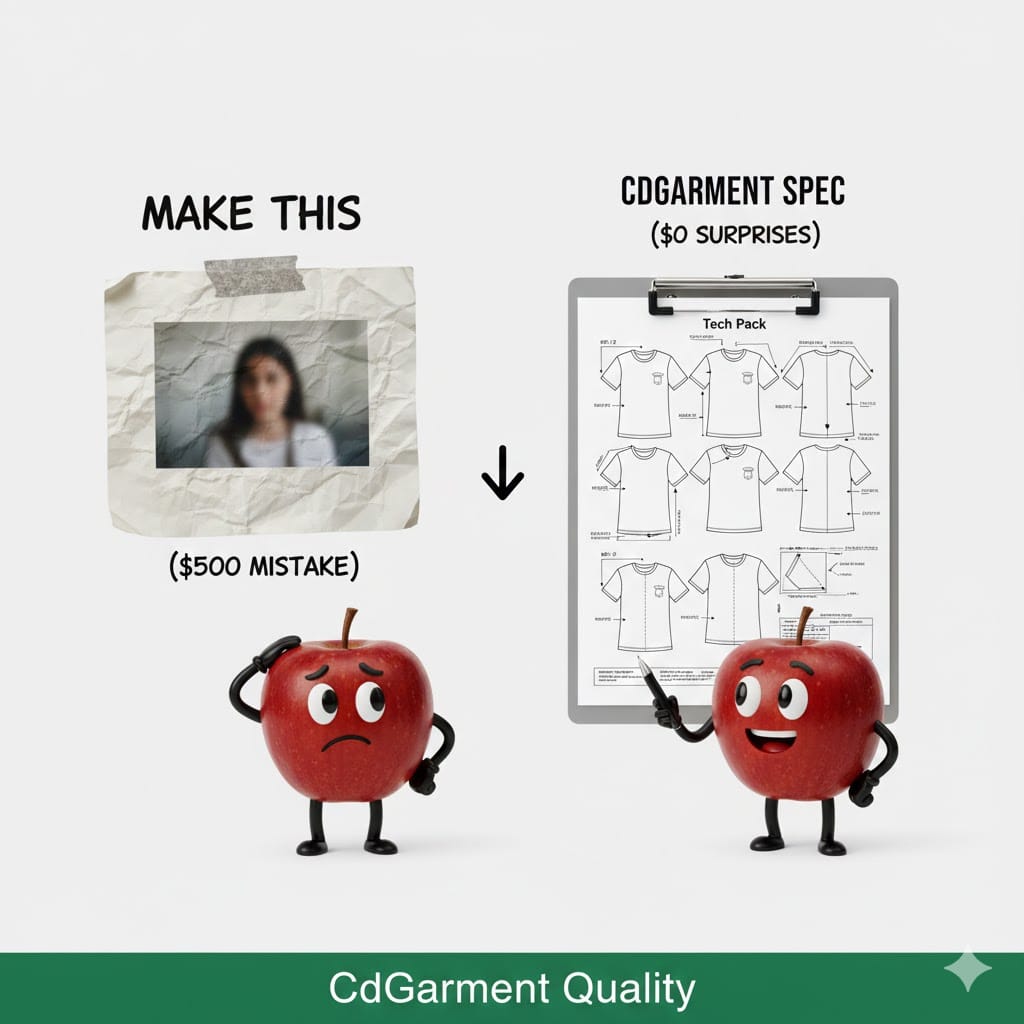

In my 20 years, I’ve seen many designers send us a single photo of a vintage shirt and say, “Make it like this.” But a photo doesn’t tell us the stitch density. It doesn’t tell us the seam allowance. It doesn’t tell us the exact placement of a label.

A “Tech Pack” is more than a list of measurements; it is the contract between your vision and our hands.

The Cost of a “Missing Detail”

When a designer provides an incomplete specification, the factory has to guess. And in manufacturing, a guess is a mistake waiting to happen. * If the Tech Pack doesn’t specify the Stitches Per Inch (SPI), the factory might use a loose stitch to save time, resulting in a seam that pops.

If the Point of Measurement (POM) isn’t clear, your “Medium” might end up with sleeves that are 2cm too short.

How CdGarment Translates Your Vision

We don’t just follow Tech Packs; we help you refine them.

The BOM (Bill of Materials): We ensure every thread, button, and zipper is documented so your 100th piece is identical to your 1st.

Clear Visual Callouts: We prefer clear diagrams over long paragraphs. A simple arrow pointing to a reinforced “Bar-tack” stitch tells our sewing team exactly where the stress points are.

The “Live” Document: As we make your first sample, we update the Tech Pack with real-world feedback (e.g., “This fabric needs a wider hem to stay flat”).

Simple Insight

A great Tech Pack is the difference between a “Guess” and a “Guarantee.” When you speak the language of technical specs, you eliminate the risk of expensive surprises.

-35-2-768x432.png)

-21-768x432.png)