Welcome To Our Official Website, And We Will Provide You With Excellent Service.

The Science of the Label: Why We Let the Labs Do the Talking

In my 20 years of manufacturing, I’ve seen brands lose entire shipments because their care labels didn’t match the actual performance of the fabric.

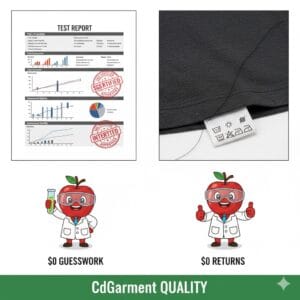

At CdGarment, we don’t leave this to chance. We don’t just “suggest” care instructions; we validate them through 3rd party laboratory testing.

A care label is a legal document. If it’s wrong, your brand is liable.

The 3rd Party Validation Process

Before bulk production begins, we send a representative “Golden Sample” to an accredited lab (such as SGS or Intertek). They put your garment through a “torture test” that no home laundry could replicate.

Fiber Composition Analysis: The lab confirms the exact percentage of cotton, polyester, or spandex. This ensures your “100% Organic Cotton” label is legally accurate and honest.

Color Fastness Testing: They test the dye’s resistance to water, light, and rubbing (Crocking). This is how we ensure that your navy blue hoodie won’t turn your customer’s white sofa blue.

Dimensional Stability (The Shrinkage Report): The lab provides a precise percentage of shrinkage. If the report shows a 5% shrink, we use that data to adjust our patterns before we cut the fabric, ensuring the customer gets the same fit after 10 washes.

From Lab Report to Finished Label

Once we receive the official Test Report, we translate those technical results into the final care symbols and text on your label.

If the lab finds high heat damages the fibers, the report will mandate “Cool Iron.”

If the dye is sensitive to oxygen-based bleaches, the report will specify “Non-Chlorine Bleach Only.”

Simple Insight

A CdGarment care label isn’t a guess; it’s the summary of a professional lab report. By investing in 3rd party testing, we provide you with a “Quality Insurance Policy” that protects your brand from returns and legal headaches.

-35-2-768x432.png)

-21-768x432.png)