Welcome To Our Official Website, And We Will Provide You With Excellent Service.

Case Study: Scaling from 200 to 10,000 Units | CdGarment

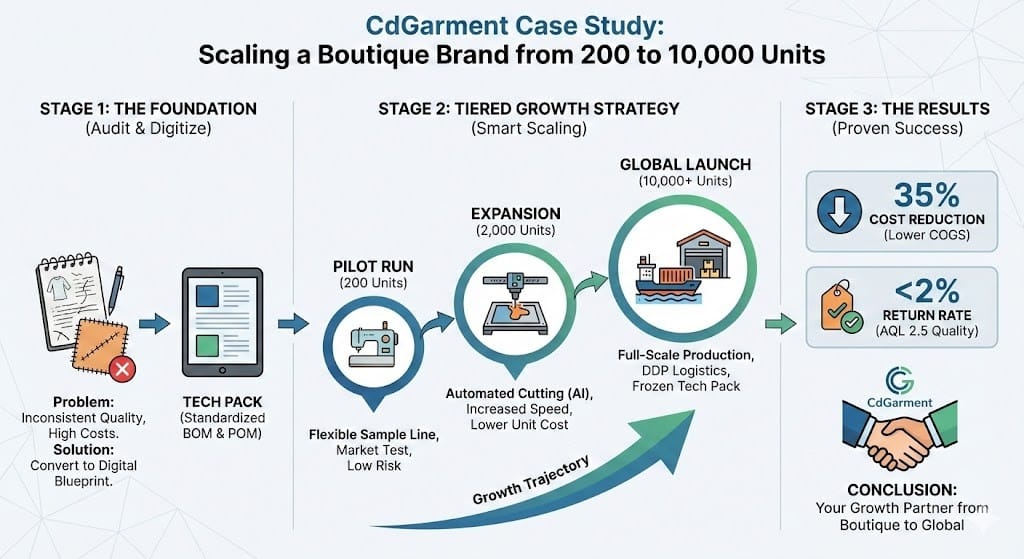

Case Study: Scaling a Boutique Brand to 10,000 Units

Many fashion entrepreneurs face the ‘Scaling Wall’—the difficult transition from small-batch boutique production to high-volume retail distribution.

At **CdGarment**, we pride ourselves on being more than just a supplier; we are a growth partner.

This **clothing manufacturer case study** highlights how we helped an emerging European brand scale their production from 200-unit test runs to 10,000-unit global shipments in just 18 months.

The Challenge: Quality Consistency at Scale

Our client, a high-end streetwear label, had found success with local small-batch tailors but faced massive quality discrepancies and rising costs when their demand spiked. They needed a partner in China who could maintain ’boutique quality’ while providing ‘industrial capacity.’

Phase 1: Refining the Foundation

We started by auditing their existing prototypes. Our technical team in Humen converted their hand-made samples into digital **apparel tech packs**. By standardizing their points of measurement (POM) and creating a unified Bill of Materials (BOM), we ensured that the garment fit would be identical whether we produced 100 pieces or 1,000.

[Image showing the growth curve of a fashion brand from 200 to 10,000 units]

Phase 2: Tiered Production & Risk Management

Rather than forcing the client into a massive upfront commitment, CdGarment implemented a **tiered growth strategy**:

* The Pilot Run (200 Units):** We used our flexible sample line to produce a market-test batch. This allowed the brand to validate their new designs with minimal inventory risk.

* The Expansion Phase (2,000 Units):** Once the designs were proven, we moved production to our automated lines, utilizing AI cutting to lower the unit cost while increasing speed.

* The Global Launch (10,000+ Units):** With a ‘frozen’ tech pack and proven quality, we executed a full-scale production run, distributed directly to their global warehouses using our DDP logistics network.

The Results: 35% Cost Reduction

By the end of the second season, the client saw a **35% reduction in COGS (Cost of Goods Sold)** due to our manufacturing efficiencies. More importantly, their return rate dropped from 12% to under 2%, thanks to our rigorous **AQL 2.5 quality control standards**.

Conclusion: Your Growth is Our Success

This success story is a blueprint for how CdGarment empowers brands. Whether you are starting with a small ‘Low MOQ’ order or preparing for a nationwide retail launch, we have the infrastructure and the expertise to scale with you.

*Ready to scale your brand?* Let’s discuss your growth roadmap today.