Welcome To Our Official Website, And We Will Provide You With Excellent Service.

How to Select the Right Knitting Factory: Insider Secrets for New Brands

The knitwear industry is growing rapidly, attracting a new generation of designers and entrepreneurs who want to create their own fashion lines. For those just getting started, one of the most important decisions is choosing the right knitting factory.

Even if you don’t have detailed technical drawings, size charts, or yarn specifications yet, the right manufacturing partner can help turn your ideas into reality. A professional knitting factory not only produces garments but also guides you through each step, helping you establish your brand with confidence.

Here’s how to select the best knitting factory for your fashion business.

1. Factory Scale and Workforce

A genuine knitting factory needs sufficient space and equipment to handle all production processes efficiently. Unlike an office, a knitting factory requires space for knitting, linking, ironing, inspection, and packaging.

At Dongguan Chuangdian Garment Factory, we operate:

Two knitwear factories and one woven garment factory

A total production area of over 26,000㎡

600+ skilled employees

Our knitwear division (11,000㎡, 230 staff) is equipped with:

36 German whole-garment knitting machines

320 multi-system automatic computer flat knitting machines (3GG–14GG)

117 automatic linking machines

30 ironing stations

Multiple inspection and packaging lines

Our woven garment factory (15,000㎡, 370 staff) includes:

5 material inspection machines

3 automatic and 2 manual cutting lines

6 hanger systems with 245 sewing machines

50 ironing stations and multiple quality control lines

A well-structured factory like ours ensures every stage of production runs smoothly—from yarn to finished garment.

2. Certifications and Compliance

Certifications are crucial for international brands, especially when working with global retailers or import/export partners. They demonstrate professionalism, ethical production, and sustainability.

Dongguan Chuangdian Garment Factory holds various certifications to meet clients’ requirements, including:

Social Responsibility: BSCI, SMETA 4P

Quality Management: ISO 9001

Sustainable Materials: BCI Cotton, RWS Wool, Organic Cotton

Recycled Yarns: GRS-certified materials

These certifications not only ensure compliance with global standards but also give our clients confidence when working with us.

3. Design Expertise and Product Style

When choosing a knitting factory, review the company’s design portfolio to ensure their product range aligns with your brand’s aesthetic.

At Dongguan Chuangdian Garment Factory, we specialize in both knitwear and woven garments, including:

Sweaters, cardigans, pullovers, knit dresses, and kids’ knitwear

Shirts, jackets, PU and denim outerwear, pants, T-shirts, and suits

With 18 years of experience, our R&D and sample teams help clients develop designs from sketches, photos, or physical samples. Whether you’re producing minimal modern knitwear or high-end fashion pieces, our team ensures that every detail reflects your brand identity.

Our export experience across Russia, Japan, the USA, Australia, South Korea, the UK, Canada, and Europe allows us to understand and meet diverse market standards.

4. Attention to Detail in Production

Quality lies in the details. A well-made knit garment should have clean finishing, even tension, and perfect shaping.

We focus on:

Neatly trimmed threads (inside and outside)

Size accuracy within ±1cm

Strong overlock and linking seams

Proper pressing and shaping with wooden boards

Reinforced seams for 3GG, 5GG, and 7GG sweaters

Smooth necklines, even ribbing, and flat garment surfaces

Each piece undergoes strict inspection before packaging—with tissue paper, moisture-control packets, and sturdy boxes—to ensure flawless delivery.

With nearly two decades of production experience, we guarantee top-quality craftsmanship that meets global standards.

5. Professional Customer Service

Behind every successful factory is an efficient and knowledgeable merchandising team.

Our team at Dongguan Chuangdian Garment Factory consists of experienced merchandisers fluent in English and well-versed in the entire manufacturing process—from yarn sourcing to delivery.

They communicate directly with clients, monitor production progress, and ensure deadlines are met. Acting as both partners and advisors, our merchandisers help clients avoid common production pitfalls and build strong long-term relationships.

6. Reliable Supply Chain for Accessories

Every garment needs quality accessories—buttons, zippers, labels, and packaging. We have built a robust accessory supply chain, allowing us to integrate all these components seamlessly based on customer requirements.

This ensures consistency in quality and faster turnaround for all custom orders.

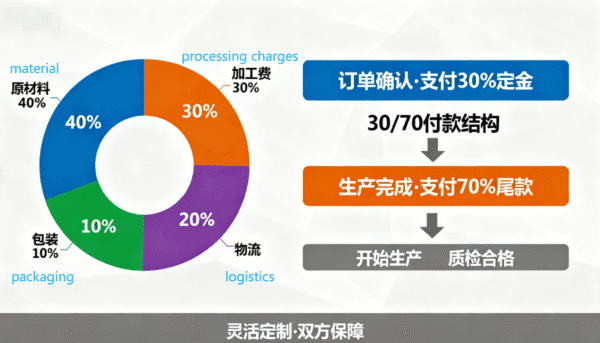

7. Understanding Costs and Payment Terms

Transparency in pricing and payment terms is essential before confirming any order. Be sure to ask about additional costs such as:

Shipping and freight

Packaging materials

Customs duties or taxes

Our typical payment terms are flexible to fit customer needs, often following a 30/70 structure (30% deposit, 70% before shipment). This provides a fair balance for both parties while ensuring smooth order management.

✅ Final Thoughts

Choosing the right knitting factory is one of the most important steps in building a successful knitwear brand. A professional manufacturer provides more than just production—they offer expertise, quality assurance, and long-term partnership.

At Dongguan Chuangdian Garment Factory, we provide OEM and ODM services for global brands. With strong technical capacity, certified quality control, and experienced communication teams, we bring your knitwear designs to life—from concept to finished product.

📩 Contact us today to discuss your next collection and discover how we can help your brand grow with high-quality knitwear and woven garments.

-35-2-768x432.png)

-21-768x432.png)