Welcome To Our Official Website, And We Will Provide You With Excellent Service.

Sweater Gauge Guide: Understanding 3G to 16G Production for Your Brand

In the world of professional knitwear manufacturing, “Gauge” is the language of precision. For a specialized manufacturer like CdGarment, gauge is not just a technical setting; it is the fundamental blueprint that determines a sweater’s weight, transparency, warmth, and luxury appeal.

Whether you are a sourcing manager for a global retailer or a creative director for a boutique label, understanding the technical spectrum of 3G to 16G is essential for optimizing your collection.

1. What Exactly is “Gauge” (G)?

In knitting, the term Gauge refers to the number of needles per inch on the knitting machine bed.

The Inverse Rule: The higher the gauge number, the more needles there are per inch. This means the needles are smaller and closer together, requiring thinner, finer yarns.

The Lower the Number: The fewer the needles, the larger they are, accommodating thick, voluminous yarns.

Choosing the right gauge is the most critical decision in the pre-production phase. It dictates the “hand-feel” of the garment and significantly impacts the final cost of production.

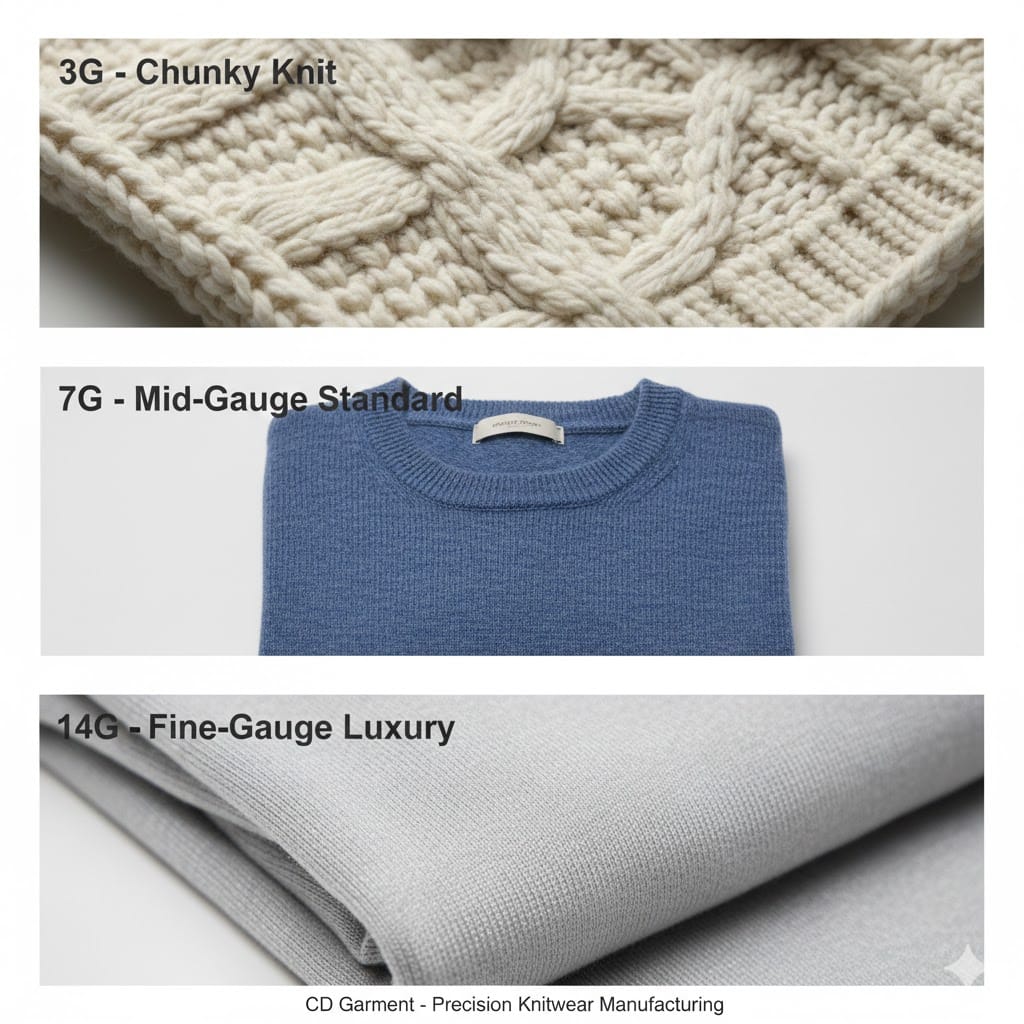

2. The CdGarment Gauge Spectrum: From Chunky to Fine

At CdGarment, our diversified manufacturing platform utilizes a wide array of flat knitting machines to serve different market needs. Here is how we categorize our production:

Low Gauge (3G – 5G): The Heavyweights

Low-gauge knitting creates the iconic “chunky” look. These machines are built for durability and maximum insulation.

Aesthetic: Bold textures, heavy cables, and “hand-knit” appearances.

Best For: Winter cardigans, outdoor “shackets,” and oversized streetwear.

Technical Note: Because these garments use more yarn by weight, material sourcing is key to managing the final price point.

Mid-Gauge (7G – 9G): The Industry Standard

The 7G to 9G range is the “sweet spot” for the global apparel market. It offers the perfect balance of warmth and layer-ability.

Aesthetic: Smooth, consistent surfaces that are excellent for school uniforms and corporate wear.

Best For: Classic V-necks, crewnecks, and the majority of children’s knitwear.

CD Advantage: Our high-speed 7G lines are optimized for high-volume efficiency without sacrificing stitch consistency.

Fine Gauge (12G – 16G): The Luxury Tiers

Fine-gauge knitting is where craftsmanship meets technology. These garments are lightweight, elegant, and feel like a “second skin.”

Aesthetic: Drape-heavy, sophisticated, and often used for high-end fashion.

Best For: Summer knits, luxury turtlenecks, and delicate silk-blend cardigans.

Technical Note: 16G production requires a pristine factory environment and superior tension control. CdGarment’s 14G and 16G lines are specifically reserved for premium fibers like extra-fine Merino and Cashmere.

3. Engineering the Perfect Fit: Matching Yarn to Machine

You cannot simply put a chunky wool yarn on a 14G machine. At CdGarment, our ODM (Original Design Manufacturer) team works closely with brands to ensure technical compatibility:

Fiber Diameter: We assist in selecting microns (thickness) of fibers that match the needle size to prevent “needle breakage” or “stiff fabric.”

Stitch Density: We calculate the exact number of loops per square inch to ensure that your 12G sweater has the perfect amount of drape without being transparent.

4. Why Gauge Matters for Your Bottom Line

For a sourcing lead, gauge selection is a financial lever.

Production Speed: Higher gauges (14G-16G) take significantly longer to knit because there are thousands of more stitches per garment, which is reflected in the lead time.

Yarn Consumption: Lower gauges use more raw material, which can increase the cost of goods (COGS) if using expensive fibers like cashmere.

Conclusion: Precision in Every Stitch

At CdGarment, we don’t just knit; we engineer. By mastering the spectrum from 3G to 16G, we provide our partners with the flexibility to design for any season, any gender, and any price point.

Choosing the right gauge is the difference between a garment that sits in a warehouse and one that becomes a customer’s favorite wardrobe staple.

-35-2-768x432.png)

-21-768x432.png)