Welcome To Our Official Website, And We Will Provide You With Excellent Service.

The CdGarment Quality Control Protocol: AQL 2.5 Standards | CdGarment

The CdGarment Quality Control Protocol: AQL 2.5 Standards

In the competitive world of fashion retail, a single faulty batch can damage a brand’s reputation and lead to costly returns.

At CdGarment, we understand that our success is built on your quality. That is why we have implemented the CdGarment Quality Control Protocol—a rigorous, multi-stage inspection system designed to meet and exceed international apparel quality control standards.

The AQL 2.5/4.0 Framework

We utilize the internationally recognized Acceptable Quality Limit (AQL) sampling method to ensure statistical reliability.

For most of our high-end garment production, we adhere to a strict AQL 2.5 for major defects and 4.0 for minor defects.

This means our tolerance for errors is among the lowest in the industry, giving you peace of mind that your shipment is retail-ready upon arrival.

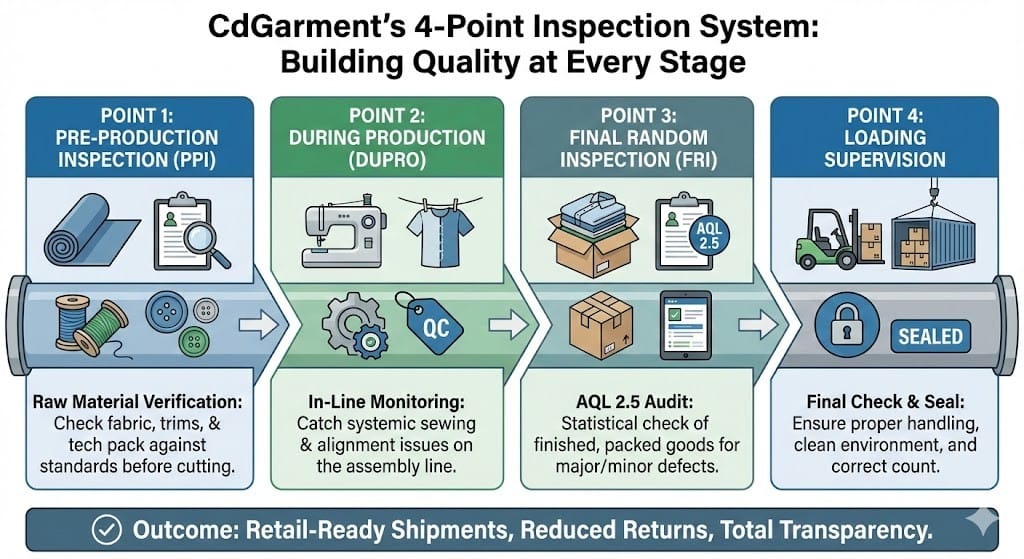

Our 4-Point Inspection System

Quality is not just checked at the end; it is built in at every stage. Our protocol includes four critical checkpoints:

1. Pre-Production Inspection (PPI): We verify all raw materials (fabrics, threads, zippers, and trims) against the approved Tech Pack before a single cut is made.

2. During Production Inspection (DUPRO): Our QC team monitors the first batch of the assembly line to catch any systemic sewing or alignment issues early.

3. Final Random Inspection (FRI): Once 100% of the order is completed and packed, our senior inspectors conduct a final audit based on the AQL sampling plan.

4. Loading Supervision: We ensure cartons are handled correctly and that the shipping environment is clean to prevent transit-related damage.

Specialized Testing Labs

Beyond visual inspections, CdGarment utilizes in-house and third-party testing for technical performance.

This includes colorfastness tests (ensuring dyes don’t bleed), shrinkage tests (verifying dimensional stability), and pull tests for buttons and snaps to ensure safety compliance, particularly for children’s wear.

Conclusion: Digital Quality Reporting

Transparency is key to our partnership. For every order, CdGarment provides a comprehensive digital QC report. This includes high-resolution photos of any identified defects, measurement charts, and a final pass/fail summary.

By adhering to these strict standards, we help our partners reduce returns and build sustainable, trusted brands.

Image Attachment