Welcome To Our Official Website, And We Will Provide You With Excellent Service.

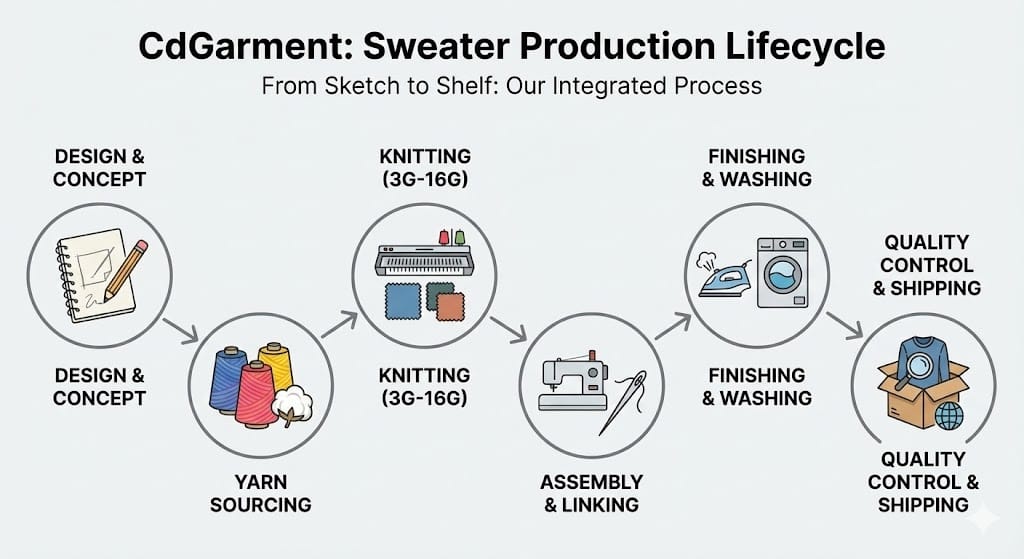

The Lifecycle of a Custom Sweater: How CdGarment Moves from Sketch to Shelf

Turning a two-dimensional sketch into a high-quality, three-dimensional garment is a journey of precision, creativity, and collaboration. For creative directors and brand owners, understanding this lifecycle is key to a successful launch. At CdGarment, we don’t just manufacture sweaters; we shepherd your vision through a meticulous process, ensuring the final product in your customer’s hands is exactly what you envisioned on paper.

Here is an inside look at the lifecycle of a custom sweater, from the initial concept to global delivery.

Phase 1: Design Consultation & Material Sourcing (The Blueprint)

Every great sweater begins with a conversation. Whether you provide a complete tech pack (OEM) or a mood board with rough sketches (ODM), this is where we define the project’s DNA.

Tech Pack Review: Our technical designers scrutinize your specifications—measurements, construction details, and artwork. We identify potential production challenges early, suggesting adjustments to improve durability or drape.

Yarn Sourcing & Selection: This is critical. Based on your target price point, season, and desired hand-feel, we guide you through our extensive library of yarns. We consider fiber composition (e.g., 100% Cashmere vs. Cotton-Silk blend), yarn count, and twist.

Gauge Selection: We help you choose the correct machine gauge (from chunky 3G to fine 16G) to achieve the right fabric weight and texture for your design.

Lab Dips: We produce small yarn samples dyed to your exact color standards (Pantone or swatch) for your approval, ensuring color consistency.

Phase 2: Prototyping & Sampling (The First Look)

Once the blueprint is approved, we move to the sampling phase. This is an iterative process designed to perfect the garment before bulk production begins.

First Proto (Prototype): Our skilled technicians create the very first physical sample. This is used to evaluate the general look, silhouette, and initial fit.

Fit Samples: Based on your feedback on the first proto, we refine the pattern and produce fit samples. These are tried on models to ensure the garment hangs correctly on the body and moves as intended.

Salesman Samples (SMS): Once the fit is finalized, we produce a small run of high-quality samples for your sales team to show to buyers and retailers.

Pre-Production Sample (PPS): This is the final “golden sample.” It is made with the actual bulk yarn, on the actual production machines, with all final details (labels, hangtags) included. Approval of the PPS is the green light for mass production.

Phase 3: Bulk Production & Quality Control (The Scale-Up)

With the PPS approved, the factory floor comes alive. This is where art meets engineering.

Knitting: Your specified yarn is loaded onto our computerized flat knitting machines. Each panel of the sweater (front, back, sleeves, trim) is knitted to the exact shape of the pattern.

Linking & Assembly: Unlike cut-and-sew garments, high-quality sweaters are “linked.” Skilled artisans use specialized linking machines to join the knitted panels together stitch-by-stitch. This creates a flat, flexible, and durable seam that is a hallmark of superior knitwear.

Washing & Treatment: The assembled sweaters undergo a specialized washing process. This is crucial for developing the final hand-feel (softness), controlling shrinkage, and removing any knitting oils.

In-Line QC: Throughout the entire process, our quality control teams conduct inspections to catch any knitting defects, needle lines, or sizing discrepancies immediately.

Phase 4: Finishing, Final Inspection & Logistics (The Final Touches)

The final phase is all about presentation and delivery.

Ironing & Steaming: Each sweater is carefully pressed on industrial steam tables to set its final shape and dimensions, giving it a crisp, professional finish.

Final Inspection: Every single garment is individually inspected a final time. We check measurements against the spec sheet, look for any remaining defects, and ensure all branding elements are perfect.

Labeling & Packing: Brand labels, care labels, and hangtags are attached. The sweaters are then folded and packed according to your specific retail requirements (e.g., individual polybags, blister packs).

Global Shipping: We coordinate with your logistics partners to ship the finished goods to your distribution centers or directly to retailers worldwide, handling all necessary export documentation.

Conclusion: The journey from a sketch to a finished sweater is a collaborative partnership. By choosing CdGarment, you gain a partner who is invested in the success of your product at every single step.

-35-2-768x432.png)

-21-768x432.png)